Static Load Tests

It has already performed approximately 400 Static Load Tests, all over Brazil.

The execution of these load tests meets the requirements of quality and follows all knowledge of the foundation elements in the most varied types of soil.

According to NB6122 / 2010 (Project and Execution of Foundations), its execution is mandatory in a large number of works.

Geofix has the teams and equipment necessary to carry out these Load Tests.

Advantages

Accurately simulate the real loads of a construction, observing the foundation's response to these loads.

EXECUTION METHODOLOGY AND CARE IMPLEMENTATION

Objective of Static Load Tests

a) Establishes the basic guidelines and conditions for the execution of the static load test applicable to several types of deep foundations, namely:

• Precast concrete piles;

• Metal piles;

• Franki piling system;

• Pipe piling;

• Root piles;

• Continuous flight auger pile with monitoring;

• Segmental flight auger piles;

• Stations;

• Diaphragm pile.

b) Establishes procedures for data collection, analysis and interpretation for:

• evaluation of the load capacity of the piles;

• measurement of displacement in the workload;

• evaluate load behavior x pile displacement.

c) specifies devices for applying increasing static forces;

d) specifies devices for obtaining the responses of applied static forces;

e) specifies equipment for record acquisition and data processing;

f) establishes the form of presenting the results.

The load test basically consists of applying static efforts to the pile and recording the corresponding displacements.

The applied forces can be axial, traction or compression or transverse.

The load test must follow ABNT NBR 12131 (Brazilian Association of Technical Standards)

Standards

NBR 6122:2010 - Design and execution of foundations - Procedure

NBR 6484:2001 - Soil - Conducting surveys for simple soil recognition - Test Method

NBR 12131:2006 - Piles - Static load test - Test method

Execution Sequence

- Make sure that there is safe access for the transport of the reaction system components, hydraulic jack and pump set, the beams and a place for risk-free assembly.

- Provide at the load proof site electricity points for feeding the jack and pump set, computer (optional) and lighting.

- Check the amount of wood for the fires before starting the assembly (simple support of the main beam), as well as the tools needed to assemble the test.

- Assembly the fire (aligned and leveled).

- Start the assembly of the Reaction System in which the accuracy of the location of the reaction piles and the pile to be tested requires care in order not to cause unforeseen efforts in the load test due to imprecise location.

- Install the main beam.

- Install the secondary beam (s).

- Install the leveled and aligned reference beams. The support must be at least 5Φ away from the pile to be tested.

NOTE: The reference beams must have sufficient inertia, so that they do not damage the readings.

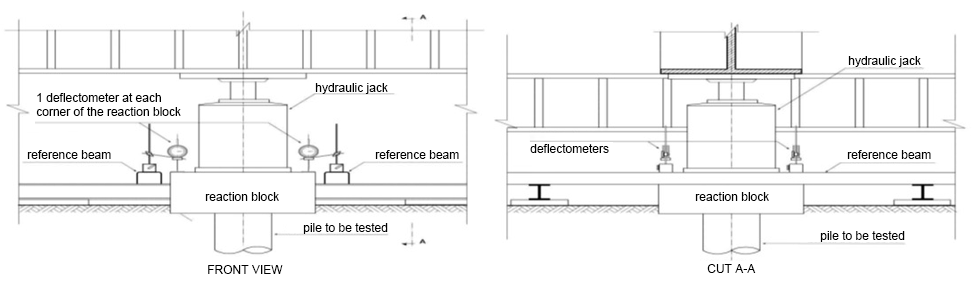

- Execute the reaction block and prepare the head or top of the profile according to the type of pile to be tested.

- Place a metal plate on the reaction block, centered in relation to the block, whose sides must be somewhat larger than the diameter of the jack.

- It is advisable to place a metal plate between the reaction beam and the jack, or when using load cell between it and the reaction beam. This action is important to avoid deformations that can occur in the beam, in order to distribute the force.

- Ensure the precise leveling of these plates using hand level (bubble) in different positions.

- Position the jack exactly in the center of the reaction block using a steel measuring tape. With this, it is possible to measure the four sides of the block and, for safety reasons, draw the diagonal checking the coincidence of the meeting between the axes.

- Ensure accurate leveling of the jack.

Reference beam and the four deflectometers positioned

- Ensure that there is no trepidation in the field, for example; equipment movement, concrete vibration, concert launch, noise, etc.

Note: This place must be protected from external disturbances, such as noise, vibrations or work performed by third parties that divert attention of the operators.

- Establish and follow the previously prepared load plan.

See other

services